The fastener industry

Fasteners are the backbone of nearly every industry, playing a crucial role in construction, automotive manufacturing, aerospace, energy, and countless other sectors. Without bolts, screws, nuts, and other fastening elements, modern infrastructure and industrial production would be impossible.

The fastener industry is vast and continuously evolving, with advancements in materials, coatings, and digital integration reshaping how fasteners are manufactured, distributed, and managed. In this article, we explore the global fastener industry, its significance, key market players, and how modern C-parts management systems are optimizing supply chains.

The Importance of Fasteners in Industrial Applications

Fasteners serve as essential components in countless applications, ranging from the simplest household furniture assembly to high-stress environments like aerospace and offshore oil platforms. The right fastener ensures structural integrity, durability, and safety.

Key Sectors Using Fasteners

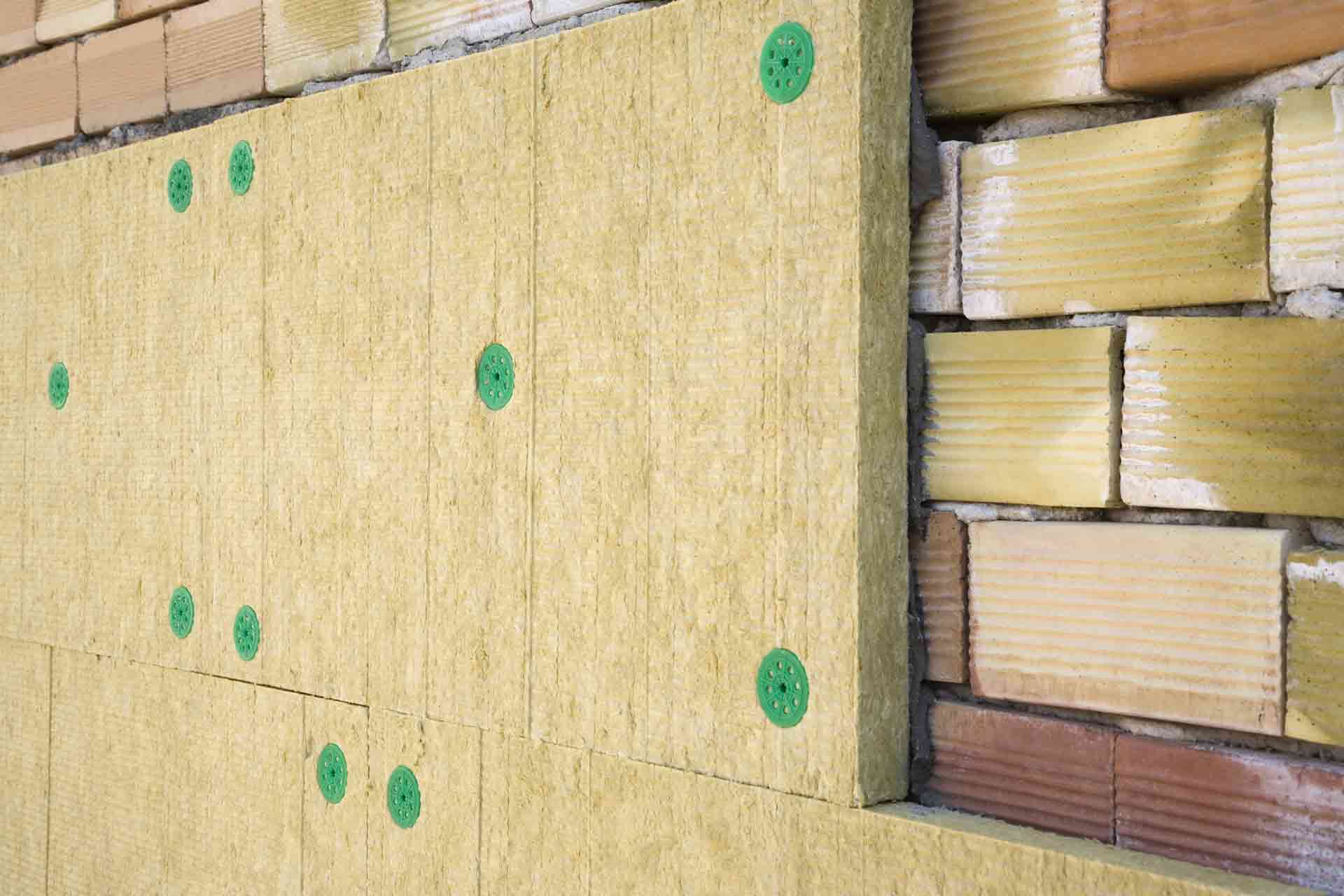

- Construction: Fasteners are vital in structural steel connections, roofing, bridges, and concrete anchoring.

- Automotive: Every vehicle contains thousands of fasteners in its engine, body panels, chassis, and interior.

- Aerospace: Precision-engineered fasteners ensure aircraft withstand extreme stresses and environmental conditions.

- Energy Sector: Wind turbines, pipelines, and power plants depend on high-performance fastening systems.

- Manufacturing & Machinery: Fasteners are integral to the production of machines and equipment across all industries.

With such a diverse range of applications, the fastener industry must continuously innovate to meet industry-specific demands.

Major Fastener Distributors in the Americas and Europe

Global distribution networks ensure that businesses have access to high-quality fasteners when and where they need them. Several companies lead the market in terms of volume, reach, and innovation.

1. Fastenal Company (USA)

Founded in 1967, Fastenal has become a major player in the industrial supply chain. The company operates over 3,600 in-market locations and offers fasteners, tools, and safety equipment. Their innovative vending machines and inventory management systems help businesses optimize stock levels.

2. Würth Group (Germany)

With over 400 companies in 80+ countries, Würth is a dominant global supplier of fasteners, screws, and assembly materials. The CPS®KANBAN and ORSY® inventory solutions help customers streamline procurement and inventory management.

3. Bossard Group (Switzerland)

A leader in fastening technology and logistics, Bossard specializes in Smart Factory Logistics and assembly technology consulting, helping manufacturers improve production efficiency.

4. Keller & Kalmbach (Germany)

A C-parts management specialist, Keller & Kalmbach offers comprehensive inventory solutions for fasteners and small components. They utilize Kanban and automated replenishment systems to ensure seamless supply chain integration.

5. Bufab Group (Sweden)

Operating in 30+ countries, Bufab focuses on both standard and custom fastener solutions. Their “Solutionist” approach helps clients optimize fastener selection and procurement processes.

6. Anixter International (USA, now part of Wesco)

A distributor of industrial components, Anixter supplies fasteners to high-tech industries, including aerospace and electronics manufacturing.

C-Parts Management: Transforming the Fastener Supply Chain

Fasteners, classified as C-parts, typically represent a small percentage of overall production costs but a large portion of procurement complexity. Managing thousands of fastener types efficiently is a challenge for manufacturers, prompting the rise of C-parts management solutions.

What Is C-Parts Management?

C-parts management focuses on optimizing the supply chain for low-value, high-quantity components, ensuring they are always available while minimizing inventory costs. This involves:

- Automated inventory replenishment using RFID and barcode systems.

- Just-in-time (JIT) delivery models to reduce stock levels.

- Supplier consolidation to simplify procurement processes.

Companies like Keller & Kalmbach, Würth, and Bossard provide specialized C-parts management solutions, helping manufacturers reduce downtime and improve efficiency.

Innovations in Fastener Technology

The fastener industry is continually innovating to improve performance, durability, and sustainability.

1. High-Performance Coatings

Corrosion resistance is critical in fasteners, especially in marine, construction, and automotive applications. Advanced coatings such as zinc-aluminum flake coatings, hot-dip galvanizing, and ceramic-based coatings help extend fastener lifespan.

2. Smart Fasteners & Digital Monitoring

With the rise of Industry 4.0, smart fasteners equipped with sensors and RFID tracking are becoming more common. These technologies provide real-time data on torque, tension, and temperature, ensuring better maintenance and safety.

3. Lightweight & High-Strength Materials

Industries like aerospace and automotive demand fasteners that are strong yet lightweight. Materials like titanium, aluminum alloys, and composite fasteners are replacing traditional steel fasteners in high-performance applications.

The Future of the Fastener Industry

The global fastener market is projected to grow steadily, driven by increased construction, infrastructure development, and advancements in manufacturing. However, challenges such as supply chain disruptions, raw material price fluctuations, and sustainability concerns will shape the industry’s future.

Key Trends to Watch:

- Growth in Sustainable Manufacturing: More companies are focusing on eco-friendly fasteners made from recycled materials.

- Advanced Digitalization: Integration of AI and IoT in inventory management and predictive maintenance.

- Expanding Globalization: Fastener suppliers continue to expand in emerging markets like India and Southeast Asia.

Conclusion

The fastener industry is an indispensable part of global infrastructure and industrial manufacturing. With leading companies driving innovation in materials, coatings, and supply chain management, fasteners are becoming more durable, efficient, and cost-effective.

As businesses adopt C-parts management solutions and embrace smart fastening technologies, the industry is set to become more streamlined and efficient. Whether in construction, automotive, aerospace, or energy, the role of fasteners will continue to be critical in building a connected and resilient world.